Made to Order

Built to Last

-

Heavy duty construction for long equipment life!

-

Engineered quality design means less down time!

Fill Out Our

Inquiry Form

or Send E-mail to

sales@doverconveyor.com

Copyright ©2006

Dover Conveyor, Inc.

All rights reserved.

|

|

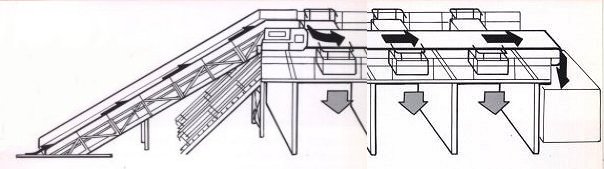

The Combo-Flite™

In-Feed

System conveys commingled

waste from an in-ground pit and deposits it at balcony level on a flat

bed sorting conveyor. The Sorting Conveyor is designed

specifically to the application. Various components can be

added to fit the nature of the installation, such as side-skirts,

winged head or tail pulleys. These

facilitate removal of such material as belting, stainless steel,

aluminum, or fiberglass sections by using magnetic separators, various

types of belting , and much more. Sorting conveyors for

Material Recovery Facilities, (MRF's), are generally made from this

type of conveyor. This category is a simple, lighter-duty

conveyor for non-severe applications where a consistent

material/substance is being transported horizontally or at a slight

incline.

|

|

Dover supplies catwalks,

handrails, and stairs for

both sides or one side, depending on work station locations. Dover also

offers safety-type interlocking electrical controls so that

the entire system can be stopped from any work

station. Dover's sequential start-up feature is

particularly useful in sorting systems to prevent material pile-up.

|

|

| Dover Picking/Sorting

Conveyors

are

available with flat or concave

beds. They are used for sorting and

segregating recyclable materials. Elevated stations simplify

sorting as materials are simply dropped through individual hopper

openings at each sorting station to ground level collection bunkers. |

Combo-Flite™

conveyor

depositing to the Picking/Sorting Conveyor at balcony

level. Dover’s stairs leading up to balcony in

foreground. \/

|

|

|

|

|

|

|

|

Conveying the Resources of the World

|

|

|

|

|